An Assembly Line Is an Example of __________.

This duel sided Assembly Line allows all aspects of the process to run smooth utilizing time to its fullest. Division of laborimplies a division of work into various part or procedures which are performed by one or gathering of laborers as indicated by their capacity and bent.

Japan The Role Of Government Britannica

Product-focused process High-volume low-variety production is best suited for which of the following process strategies.

. A product layout 2. Assembly line production has its roots in manufacturing and is often associated with Henry Ford and the mass production of automobiles. An assembly line is an example of Exam Question An assembly line is an example of 1.

Whereas large machines had previously been mass-produced from a single location to which large stocks of components were hauled Fords innovation was to install a moving assembly line in which identical parts could be added to the. The conveyor belt runs through the factory. An assembly line is an example of division of labor.

The service workflow was broken down in the following stages. Aside from assembly line industries piece rate industries are perhaps the best examples of complete contracts leading to high rates of unionization. For example a food factory may use a production line to apply a series of food processing and packaging stepsAssembly line is specific to production lines that assemble something by adding parts and components in a series of steps.

A process layout 3. Assembly Line A manufacturing process invented by Henry Ford in which parts usually interchangeable parts are added to a product in a sequential manner using optimally planned logistics to create a finished product much faster than with handcrafting-type methods. Development of Assembly Line.

A process for turning out a finished product in a mechanically efficient manner academic assembly lines. 1 receiving order 2 dow preparation 3 adding ingredients 4 place pizza in oven 5 assembly pizza box 6 content verification 7 delivery bag preparation 8 delivery process. Repetitive process Which of the following transformations generally has the highest equipment utilization.

A certain restaurant is designing an assembly line for a pizza delivery service. The MOV and ADD is the mnemonic command to move the number 3 into a part of the. A factory assembly line is literally a line where something is put together typically on a conveyor belt of some sort.

For instance mass-market jewelers often use assembly lines in which materials are handed from one worker to another without the benefit of machinery. Division of laboris a financial ideathat expresses that partitioning and the creation procedure into various stages empowers. In most cases a manufacturing assembly line is a.

A fixed position layout 4. ADD eax ebx ecx. Here is an example of assembly language.

Generally production assembly line is partially automated system in which product moves through the process. Definition of assembly line Entry 2 of 2 1. Production line is a broad term that can include manufacturing processes that dont involve parts.

Work Cell and Conveyor This Work Cell and Conveyor System enables the finished product t. The assembly line is a production process wherein compatible areas are included in product in sequenced style to set up a final product. An assembly line is a manufacturing process in which interchangeable parts are added to a product in a sequential manner to create an end product.

Assembly Line Examples Assembly Line with Conveyor Continuous flow in an Assembly Line is crucial to its success. It was in this context that Henry Ford first launched his constant motion assembly line for the manufacture of the Model T Ford in 1913. See answer 1 Best Answer.

An intermittent organization Answer Practice set and Exam Quiz Yes. From the Cambridge English Corpus For instance assembly line industries tend to be highly unionized. Assembly Line Example A very common and well known example is car manufacturing where a lot of parts are assembled one by one to create the final automobile.

The assembly line is often described as a process that uses machines to move material from one place to another but in practice machines are not always needed. Fords inspiration for moving to a continuous-flow production methodology likely came from several. An arrangement of machines equipment and workers in which work passes from operation to operation in direct line until the product is assembled.

A flexible manufacturing system An assembly line is an example of a __________. The below code signals to a processor in binary code to add the numbers 3 and 4. An assembly line is a production methodology that breaks a process down into discrete steps that are executed in an iterative manner.

In this example 1 is the label which lets the computer know where to begin the operation. At every station across the line certain portion of the manufacturing process occurs. The process can start from engine fitting and then the car moves to chassis assembly.

Chapter 2 Business Basics Ppt Video Online Download

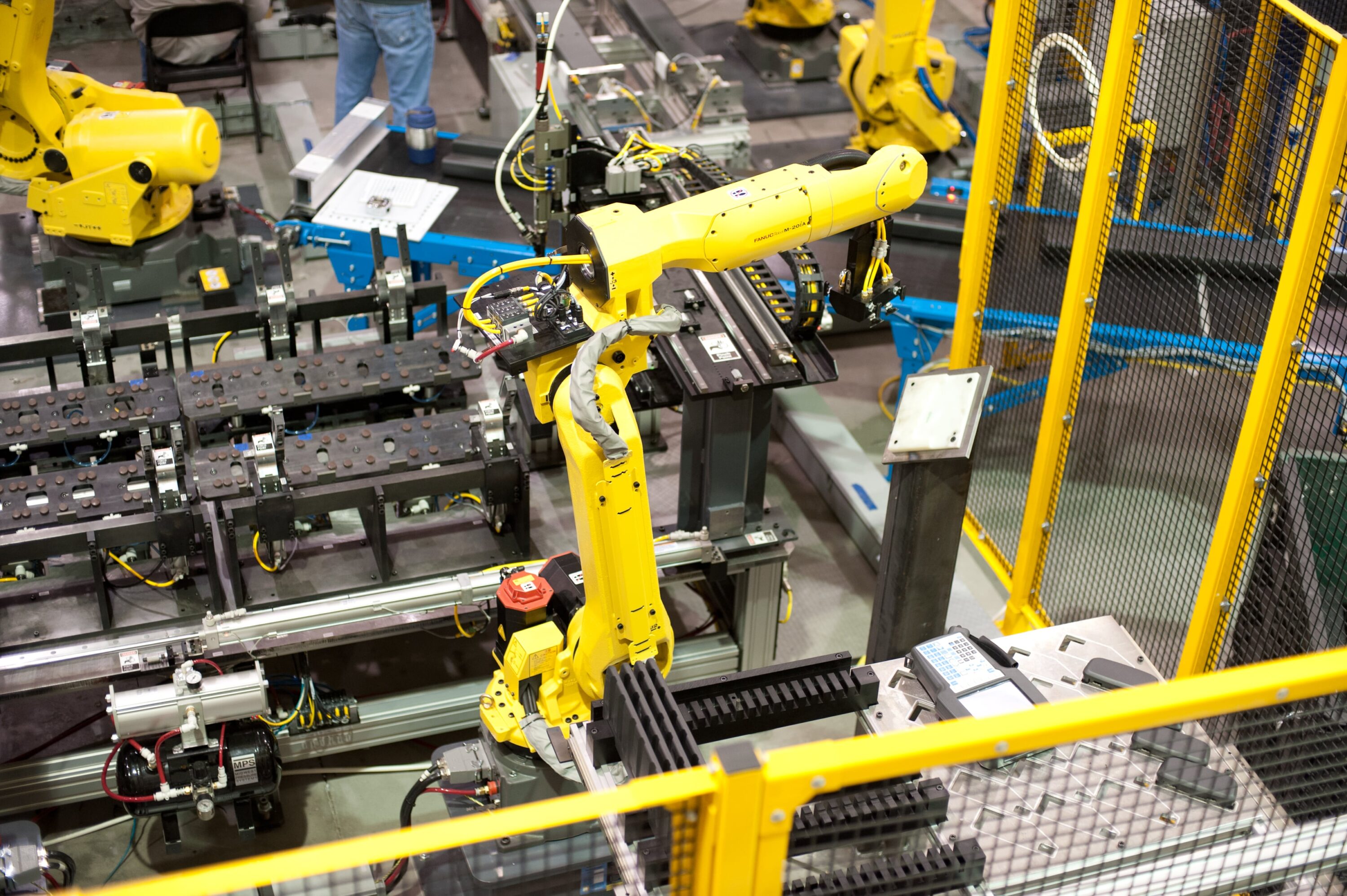

Automotive Robots Assembly Line Automation

Layout System Examples Advantages Type Disadvantages System Process Layout

Comments

Post a Comment